All modern name-brand motor oils meet numerous industry standards for performance, which provides a comforting assurance that these are good lubricants. However, drivers should consider that such standards only set baselines for minimum performance and that great lubricants go far beyond such minimum requirements when it comes to protecting your car’s engine.

This is particularly true of modern threats to your engine’s well-being that have emerged as a result of changing technology.

“Valvoline supports the industry standards,” stated Valvoline engineer Michael Warholic. “Without standards, it’s the Wild West.” The thing is that standards cover only agreed-upon minimum requirements for engine wear, carbon deposits, fuel economy, and other critical performance parameters.

“Even though an oil on the shelf is approved and licensed by the American Petroleum Institute, it can be a borderline oil and may only provide minimum quality,” Warholic cautioned. “We aim to provide performance above and beyond the minimum standards by adding boosters to improve performance."

Industry standards take time to develop, so they may not necessarily provide the needed performance of new cars’ engines.

“It may take six or seven years to develop an engine test,” explained Warholic. “They are difficult to design, taking great effort to ensure accuracy and repeatability.” Internal combustion engine technology is evolving so quickly now that seven years after a new engine launch it may be due for replacement. “The engine is almost through its lifecycle, so you are always behind the curve,” he said.

As a result, the latest engines need much more than current standards require. That is why Valvoline has developed Valvoline Modern Engine motor oil to exceed these standards and protect modern turbocharged, gasoline direct-injected engines from their unique threats.

“With our Modern Engine oil, the performance is light years away from that minimum standard,” Warholic said. “The new engines may be more abusive to oil and require a higher standard.”

An emerging problem with direct-injected engines is the accumulation of carbon deposits on intake valves. Unlike port-injected engines where the fuel flows over the intake valve, direct-injected engines squirt the fuel directly in the combustion chamber. As a result, the intake valves are not cleaned as well.

Injecting gas directly into the combustion chamber provides the potential for improved power and efficiency, but it may leave intake valves with tiny amounts of oil seeping past their seals to get baked onto the valve.

“There is no test for intake valve deposits currently in the industry specifications,” Warholic said. “This problem is not addressed by the industry at this point, and there is no minimum standard for intake valve deposits.”

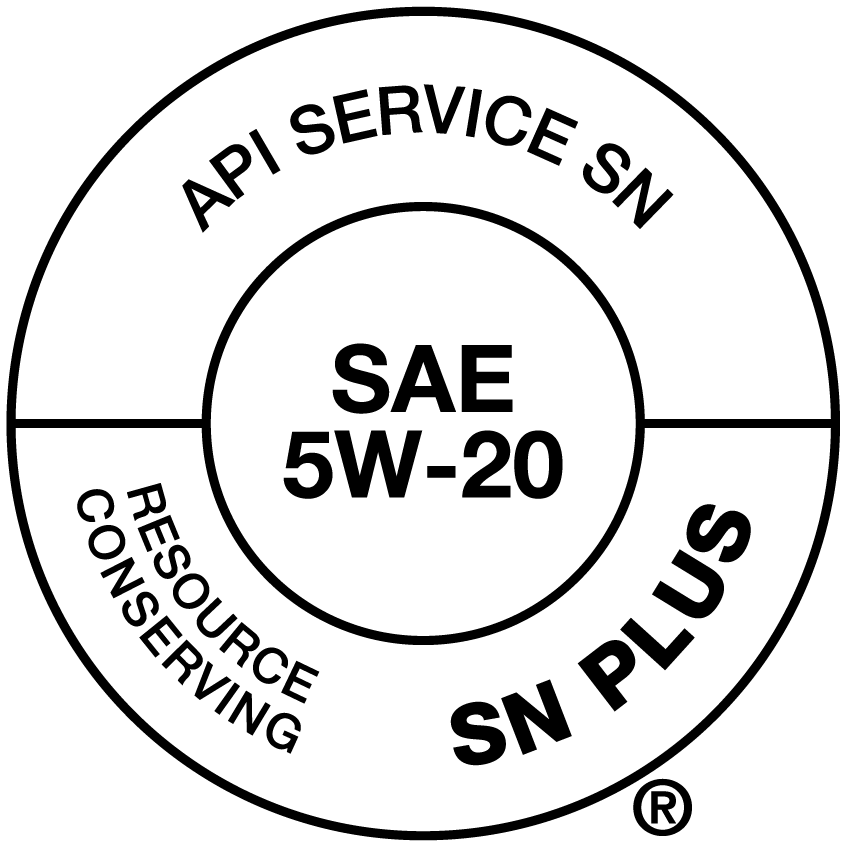

The American Petroleum Institute “SN” designation for motor oil dates back to 2010 and was created to help protect turbochargers, improve efficiency, work with ethanol fuel, and protect emissions systems. Those are all important factors that were emerging in the 2000s. But engine technology has continued to evolve with the widespread adoption of direct fuel injection, and that has introduced new challenges such as intake valve deposits.

Carmakers can point to the ASTM International (originally the American Society for Testing Materials) 5500-18 gasoline standard that originated in 1994 and was updated just last year. It focuses on minimizing deposits on intake valves, while the equally new 5598-18 standard targets preventing clogged fuel injectors.

These may appear relevant to the problem of carbon buildup on intake valves. But those fuel tests were done using an obsolete 1985 BMW 318i’s engine. That engine was designed in the late 1950s, debuted in 1961, and by 1985 was fitted with Bosch K-Jetronic mechanical port fuel injection, so it is very far from the finely tuned engines of today’s cars.

The biggest issue is that the old BMW engine employs port-fuel injection. So while it can be used to test for intake valve deposits that can be left by gasoline, it is not useful for watching for those that accumulate in the absence of gas in the intake port, as is the case with direct-injected engines.

“Cleaning injectors, that’s good,” observed Warholic. “But that is nowhere near the intake valve, so it is addressing a problem but not the intake valve problem.” When drivers are told to buy high-quality gasoline to avoid intake port deposits, they need to consider that the quality of the gas cannot make a difference if that gas never contacts the intake valves.

Instead, the solution is to buy a motor oil such as Valvoline Modern Engine that is specifically designed to minimize the build-up of carbon on the intake valves that occurs when that oil seeps past the valve seals.

Vehicle manufacturers and the API do not include an intake valve deposit test in the current industry standards. Even if they did, those standards will be for minimum permissible performance. Valvoline Modern Engine oil is the only solution to this problem today, and because Valvoline always exceeds the minimum standards, it will remain so even after others achieve any future certification by standards bodies.

- The content above was submitted by a guest contributor and is for informational purposes only. The views and opinions expressed in this content are those of the guest contributor and do not reflect the views and opinions of Valvoline LLC.

Dan Carney

Dan Carney